WE TAKE UP WORKS OF ANY COMPLICATION

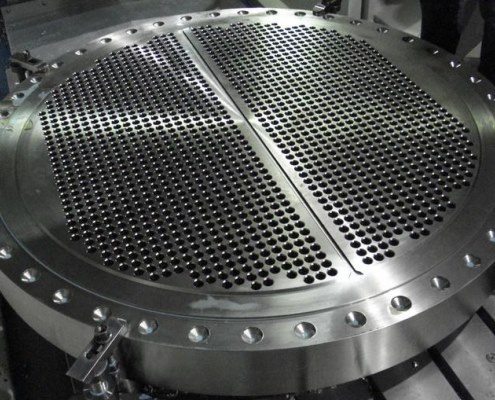

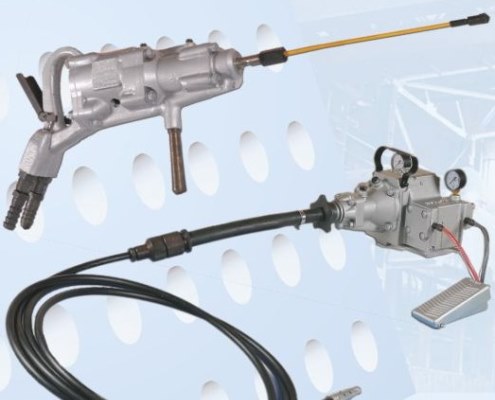

We worked out unique technology of cleaning of equipment, allowing to liquidate any degree of muddiness and return their initial state to the wares.

WE RELEASE FROM PROBLEMS FOR A LONG TIME

Equipment and capacities, transport and metallic constructions – all of them need a reliable corrosion protection. And we are able to do her so that a result made happy you long years!

FACEBOOK

FACEBOOK